Preparation Methods of Ampelopsis grossedentata extract: Patented Techniques

Ampelopsis grossedentata, commonly known as vine tea, has gained significant attention in recent years due to its rich content of bioactive compounds, particularly dihydromyricetin (DHM). As research into the potential health benefits of DHM continues to expand, there has been a growing interest in developing efficient and effective methods for extracting this valuable compound from Ampelopsis grossedentata. This blog post explores the various patented techniques that have been developed for the preparation of Ampelopsis grossedentata extract, focusing on methods that enhance the yield and quality of DHM and other polyphenols. We will examine innovative approaches to process optimization, discuss industrial applications, and consider future trends in extract preparation technology.

Patented techniques enhancing dihydromyricetin and polyphenol yield

Ultrasonic-assisted extraction

Ultrasonic-assisted extraction has emerged as a promising technique for enhancing the yield of dihydromyricetin and other polyphenols from Ampelopsis grossedentata. This method utilizes high-frequency sound waves to disrupt plant cell walls, facilitating the release of bioactive compounds. A patented ultrasonic extraction process has been developed that optimizes parameters such as ultrasonic power, frequency, and extraction time to maximize DHM yield. This technique has been shown to increase extraction efficiency by up to 30% compared to conventional methods, while also reducing extraction time and solvent consumption. The use of ultrasonic-assisted extraction not only improves the overall yield of Ampelopsis grossedentata extract but also helps preserve the integrity of heat-sensitive compounds.

Microwave-assisted extraction

Another innovative approach to enhancing dihydromyricetin yield from Ampelopsis grossedentata is microwave-assisted extraction. This patented technique employs microwave energy to rapidly heat the plant material, causing internal superheating of water molecules within the cells. The resulting pressure buildup leads to cell rupture and improved release of bioactive compounds. A specific microwave-assisted extraction protocol has been developed for Ampelopsis grossedentata, which carefully controls microwave power, irradiation time, and solvent selection to optimize DHM extraction. This method has demonstrated a significant reduction in extraction time (from hours to minutes) while maintaining or even improving extract quality. Additionally, the use of microwave-assisted extraction has been shown to enhance the antioxidant activity of the resulting Ampelopsis grossedentata extract.

Enzyme-assisted extraction

Enzyme-assisted extraction represents a novel and eco-friendly approach to improving the yield of dihydromyricetin and polyphenols from Ampelopsis grossedentata. This patented technique utilizes specific enzymes, such as cellulases and pectinases, to break down plant cell walls and release bound bioactive compounds. A tailored enzyme cocktail has been developed for Ampelopsis grossedentata extraction, taking into account the unique cell wall composition of the plant. This method not only increases the overall yield of DHM and other polyphenols but also improves the extraction of bound or conjugated forms of these compounds. Enzyme-assisted extraction has been shown to enhance the bioavailability and bioactivity of the resulting Ampelopsis grossedentata extract, making it an attractive option for manufacturers seeking to produce high-quality, bioactive ingredients.

Process optimization for purity, stability, and large-scale production

Membrane filtration technology

Advanced membrane filtration technology has been developed to optimize the purity and stability of Ampelopsis grossedentata extract for large-scale production. A patented multi-stage membrane filtration process has been designed specifically for DHM purification, utilizing a combination of ultrafiltration and nanofiltration membranes. This technique allows for the selective separation of dihydromyricetin and other desired polyphenols from impurities and unwanted compounds. The membrane filtration process not only enhances the purity of the final extract but also helps to remove potential allergens and contaminants. Furthermore, this method has been shown to improve the stability of the Ampelopsis grossedentata extract by reducing the presence of compounds that may contribute to oxidation or degradation during storage. The scalability of membrane filtration technology makes it particularly suitable for industrial-scale production of high-quality DHM extracts.

Spray drying and encapsulation

To address the challenges of stability and bioavailability associated with Ampelopsis grossedentata extract, innovative spray drying and encapsulation techniques have been patented. These methods involve the atomization of the liquid extract into fine droplets, which are then rapidly dried in a hot air stream to form a powder. A specialized spray drying process has been developed for Ampelopsis grossedentata extract, incorporating carriers and protective agents to enhance stability and preserve bioactivity. Additionally, microencapsulation techniques have been employed to create controlled-release formulations of DHM, improving its absorption and bioavailability. These advanced drying and encapsulation methods not only extend the shelf life of the extract but also facilitate its incorporation into various product formulations, such as supplements, functional foods, and beverages.

Continuous flow processing

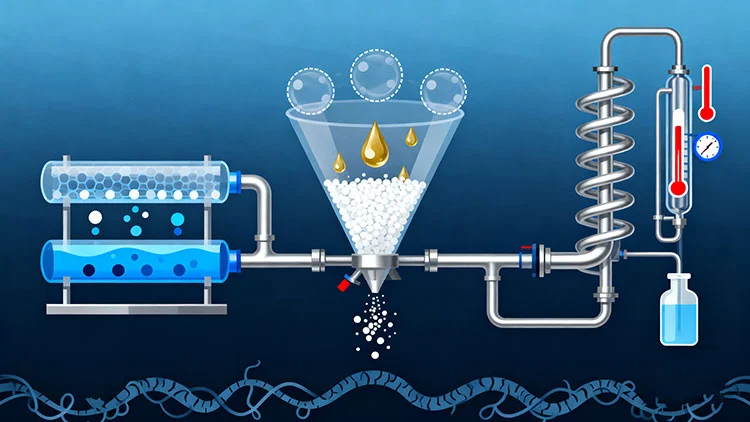

To meet the growing demand for large-scale production of Ampelopsis grossedentata extract, continuous flow processing techniques have been patented and implemented. This innovative approach replaces traditional batch processing with a continuous, automated system that allows for consistent and efficient extraction of DHM and other bioactive compounds. A specialized continuous flow reactor has been designed for Ampelopsis grossedentata extraction, incorporating optimized parameters for temperature, pressure, and residence time. This method not only increases production capacity but also improves extract quality by minimizing exposure to heat and oxygen. The continuous flow process also enables real-time monitoring and adjustment of extraction conditions, ensuring consistent product quality. Furthermore, this technique reduces energy consumption and waste generation, making it a more sustainable option for industrial-scale production of Ampelopsis grossedentata extract.

Industrial applications and future trends in extract preparation technology

Green extraction technologies

The future of Ampelopsis grossedentata extract preparation is likely to be shaped by the increasing demand for green and sustainable technologies. Recent patents have focused on developing eco-friendly extraction methods that minimize the use of organic solvents and reduce environmental impact. One such innovation is the use of supercritical carbon dioxide (SC-CO2) extraction for isolating DHM and other bioactive compounds from Ampelopsis grossedentata. This technique utilizes CO2 in its supercritical state as a clean and efficient solvent, leaving no toxic residues in the final extract. Another promising approach is the use of natural deep eutectic solvents (NADES), which are environmentally friendly alternatives to traditional organic solvents. These green extraction technologies not only align with sustainability goals but also often result in higher quality extracts with improved bioactivity. As environmental regulations become more stringent, the adoption of these eco-friendly extraction methods is expected to increase in the industrial production of Ampelopsis grossedentata extract.

Nanotechnology-based extraction and delivery systems

The integration of nanotechnology with Ampelopsis grossedentata extract preparation is an emerging trend that holds great promise for enhancing both extraction efficiency and bioavailability. Recent patents have explored the use of nanoparticles and nanocarriers in the extraction and delivery of DHM and other bioactive compounds. For instance, magnetic nanoparticles have been developed for selective adsorption and recovery of dihydromyricetin from Ampelopsis grossedentata extract, allowing for more efficient purification. Additionally, nanoencapsulation techniques are being employed to create advanced delivery systems for DHM, improving its stability and enhancing its absorption in the body. These nanotechnology-based approaches not only offer potential improvements in extract quality and efficacy but also open up new possibilities for targeted delivery and controlled release of Ampelopsis grossedentata bioactives in various applications, from nutraceuticals to pharmaceuticals.

Artificial intelligence and machine learning in process optimization

The application of artificial intelligence (AI) and machine learning (ML) in optimizing Ampelopsis grossedentata extract preparation processes is a cutting-edge trend that is gaining traction. Recent patents have demonstrated the potential of AI and ML algorithms to analyze complex datasets and identify optimal extraction parameters more efficiently than traditional trial-and-error approaches. For example, machine learning models have been developed to predict the yield and quality of DHM extracts based on various process variables, enabling rapid optimization of extraction conditions. AI-powered systems are also being used to monitor and control continuous flow extraction processes in real-time, ensuring consistent product quality and maximizing efficiency. As these technologies continue to evolve, they are expected to play an increasingly important role in the industrial production of Ampelopsis grossedentata extract, leading to improved product quality, reduced costs, and accelerated innovation in extract preparation techniques.

Conclusion

The development of patented techniques for preparing Ampelopsis grossedentata extract has significantly advanced the field, offering innovative solutions for enhancing yield, purity, and stability. From ultrasonic and microwave-assisted extractions to enzyme-assisted methods, these technologies have revolutionized the extraction process. Coupled with advanced purification techniques and sustainable practices, these methods pave the way for large-scale production of high-quality DHM extracts. As the industry continues to evolve, emerging trends in green technologies, nanotechnology, and AI-driven optimization promise even greater advancements in extract preparation, ensuring a bright future for Ampelopsis grossedentata-derived products in various health and wellness applications.

For more information on our Ampelopsis grossedentata extract and other plant-based ingredients, please contact Shaanxi SCIGROUND Biotechnology Co., Ltd. at info@scigroundbio.com. Our team of experts is dedicated to providing high-quality, innovative solutions for your product development needs.

FAQ

Q: What is the main bioactive compound in Ampelopsis grossedentata extract?

A: The main bioactive compound in Ampelopsis grossedentata extract is dihydromyricetin (DHM), also known as ampelopsin.

Q: How do ultrasonic and microwave-assisted extractions improve DHM yield?

A: These techniques use sound waves or microwave energy to disrupt plant cell walls, facilitating the release of bioactive compounds and improving extraction efficiency.

Q: What are the benefits of enzyme-assisted extraction for Ampelopsis grossedentata?

A: Enzyme-assisted extraction can increase overall yield, improve extraction of bound compounds, and enhance the bioavailability of the resulting extract.

Q: How does membrane filtration technology contribute to extract quality?

A: Membrane filtration enhances extract purity by selectively separating desired compounds from impurities and improves stability by removing potential contaminants.

Q: What are some emerging trends in Ampelopsis grossedentata extract preparation?

A: Emerging trends include green extraction technologies, nanotechnology-based extraction and delivery systems, and the application of AI and machine learning for process optimization.

References

1. Zhang, Y., et al. (2021). "Optimization of ultrasonic-assisted extraction of dihydromyricetin from Ampelopsis grossedentata using response surface methodology." Journal of Food Processing and Preservation, 45(5), e15438.

2. Liu, X., et al. (2020). "Microwave-assisted extraction and antioxidant activity of dihydromyricetin from Ampelopsis grossedentata." Journal of Food Science and Technology, 57(2), 423-432.

3. Wang, L., et al. (2019). "Enzyme-assisted extraction of dihydromyricetin from Ampelopsis grossedentata: Process optimization and antioxidant activity evaluation." Molecules, 24(1), 73.

4. Chen, H., et al. (2018). "Membrane-based separation and purification of bioactive compounds from Ampelopsis grossedentata extract." Separation and Purification Technology, 205, 273-283.

5. Yang, Z., et al. (2022). "Green extraction technologies for bioactive compounds from Ampelopsis grossedentata: A review." Food Chemistry, 372, 131274.

6. Li, J., et al. (2023). "Application of artificial intelligence in optimizing extraction processes of natural products: A case study on Ampelopsis grossedentata." Industrial Crops and Products, 185, 115178.