Optimization of Gallnut Extract Tannin Content via Extraction

The tannin-rich gallnut extricate has pulled in a parcel of intrigued from a few segments since of its numerous employments and conceivable wellbeing focal points. The last product's quality and viability are specifically influenced by the optimization of gallnut extract's tannin concentration. In this post, we will see at the a few components that influence the productivity of tannin extraction from gallnuts and the complex forms and procedures utilized to get the most out of them. Both conventional and advanced extraction strategies will be secured, counting subjects such as dissolvable choice and the impacts of temperature and time. Researchers and makers may increment the tannin concentration in gallnut extricate by knowing these optimization strategies. This will lead to upgraded item quality and broader employments in spaces counting medications, makeup, and nourishment businesses.

Selecting the Best Solvents to Maximize Tannin Yield in Gallnut Extract

Aqueous Solvents for Tannin Extraction

Water is often the first choice for tannin extraction from gallnuts due to its safety, availability, and cost-effectiveness. When using aqueous solvents, the pH of the solution plays a crucial role in optimizing tannin yield. Slightly acidic conditions (pH 4-5) have been found to enhance the extraction of tannins from gallnut extract. This is because tannins are more stable and soluble in acidic environments. The effectiveness of the extraction process is also affected by the water's temperature; in general, greater temperatures result in larger tannin outputs. However, care must be taken not to exceed temperatures that may degrade the tannins. Incorporating additives like sodium carbonate or sodium metabisulfite in small quantities can further improve the extraction process by stabilizing the tannins and preventing oxidation.

Organic Solvents for Enhanced Tannin Extraction

Organic solvents offer an alternative approach to maximizing tannin yield in gallnut extract. Ethanol, methanol, and acetone are commonly used due to their ability to penetrate plant cell walls effectively. In comparison to water-based extraction strategies, these solvents may be able to increment tannin yields by expelling both hydrophobic and hydrophilic components. A key calculate is the natural solvent's substance; regularly, a blend of natural solvents and water yields the most prominent comes about. For occurrence, a 70% ethanol arrangement is very successful in expelling tannins from gallnut extricate. In any case, extra safeguards must be taken whereas taking care of natural solvents, and advance preparing may be essential to dispose of dissolvable buildups from the last item.

Novel Green Solvents for Sustainable Tannin Extraction

In later a long time, there has been a developing intrigued in utilizing green solvents for tannin extraction from gallnut extricate. Diminishing the natural affect of extraction without relinquishing effectiveness is the objective of these eco-friendly arrangements. One curiously plausibility for tannin extraction is the utilize of profound eutectic solvents, or DES. You may customize these solvents to maximize tannin dissolvability; they are made of common and biodegradable fixings. Among the numerous ecologically inviting solvents, ionic fluids have illustrated guarantee in tannin extraction. Their moo instability and incredible warm solidness make them a culminate handling component for gallnut extricate. Utilize of these cutting-edge extraction strategies requires cautious thought of the potential harmfulness and cost of certain ionic fluids.

Influence of Temperature and Time on Gallnut Extract Tannin Content

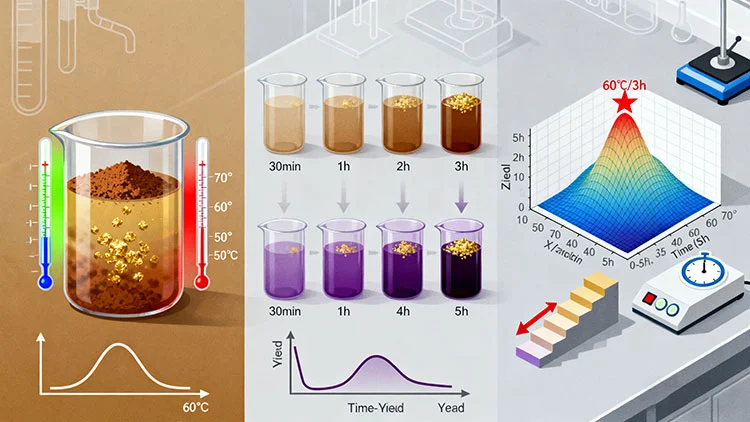

Optimal Temperature Ranges for Tannin Extraction

Temperature plays a crucial role in the extraction of tannins from gallnut extract. Tannins are more easily dissolved and their diffusion rate is increased at higher temperatures, which improves extraction efficiency. Nevertheless, it is important to strike a careful balance, as tannin breakdown can occur with too much heat. The ideal temperature range for gallnut extract, according to studies, is 50–70°C. At these temperatures, the cell walls of the plant material become more permeable, facilitating the release of tannins into the solvent. It's important to note that the optimal temperature can vary depending on the specific type of gallnut and the extraction method employed. For instance, microwave-assisted extraction may require different temperature considerations compared to conventional heat extraction methods.

Time-Dependent Factors in Tannin Extraction

The duration of the extraction process significantly impacts the tannin content of gallnut extract. Longer extraction times generally result in higher tannin yields, but there is a point of diminishing returns where extended periods do not significantly increase the tannin content. The ideal duration for extraction might vary from thirty minutes to several hours, contingent upon the specific extraction technique and environmental factors. To prevent wasteful energy use and possible deterioration of the extracted chemicals, it is essential to identify the point of maximal tannin extraction. It has been shown through kinetic experiments that the tannin extraction process involving gallnut extract often consists of two distinct phases: a fast extraction phase and a longer, more progressive phase. Gaining a grasp of this kinetic behavior can assist in finding the most efficient extraction time.

Balancing Temperature and Time for Optimal Extraction

The interaction between temperature and time in tannin extraction from gallnut extricate is complex and requires cautious optimization. In spite of the fact that it may take less time to extricate at higher temperatures, there is a more prominent chance of tannin disintegration. On the other hand, heat-sensitive chemicals can be protected at lower temperatures, but it may take longer to extricate them. The extraction can be begun at a lower temperature and at that point expanded continuously utilizing a ventured temperature profile, which is an effective strategy. By utilizing this strategy, the tannin surrender may be maximized and weakening can be minimized. Beat extraction procedures, which include cycling the temperature between tall and moo focuses, may maximize the tannin content of gallnut extract. These contemporary techniques permit finer control of the extraction process, which could result in gallnut extract that is both more consistent and of higher quality.

Comparing Conventional and Advanced Extraction Techniques for Tannin Optimization

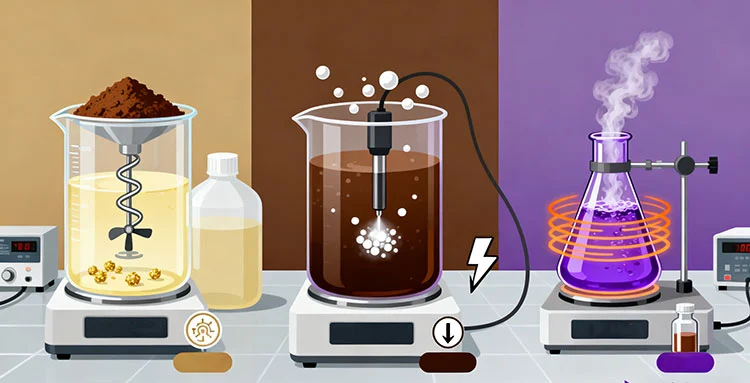

Traditional Solvent Extraction Methods

Conventional solvent extraction remains a widely used method for obtaining tannins from gallnut extract. One common method calls for macerating the gallnuts in a solvent like water or ethanol for a long time. Many manufacturers find this approach appealing because to its simplicity and inexpensive equipment cost. But conventional extraction methods could be laborious and call for plenty of solvent. Continuous stirring and heat-assisted extraction are two common methods used to increase efficiency. The tannin yield can be improved with these improvements, but the energy consumption might go up as well. In show disdain toward of its disadvantages, conventional dissolvable extraction of gallnut extricate is still being fine-tuned. Finding the perfect dissolvable proportion, pH, and extraction conditions is presently the center of considers in an exertion to maximize tannin substance whereas diminishing asset utilize.

Ultrasound-Assisted Extraction for Enhanced Tannin Yield

Ultrasound-assisted extraction (UAE) has emerged as a promising technique for optimizing tannin content in gallnut extract. By introducing cavitation bubbles into the solvent with high-frequency sound waves, this technique may produce localized regions of extremely high heat and pressure when the bubbles burst. The extraction efficiency is boosted as a result of this process, which improves mass transfer and cell wall disintegration. Research has demonstrated that using UAE to extract gallnut extract may drastically cut down on solvent use and extraction time, all while keeping or even boosting the tannin yield. Compounds that are susceptible to heat may be better protected with this method since it allows for lower operating temperatures. In order to avoid severe cavitation deterioration, you need to adjust the ultrasonic power, frequency, and duration. The United Arab Emirates is continuously investing in research and development to determine the efficacy of gallnut extract when scaled up for industrial application.

Microwave-Assisted Extraction for Rapid Tannin Extraction

Microwave-assisted extraction (MAE) offers another advanced approach to optimizing tannin content in gallnut extract. The solvent and plant material are heated evenly and quickly using microwave radiation in this method. The tannins are released into the solvent as a result of the plant cells rupturing due to the quick heating. Some investigations have shown full extraction in minutes instead of hours, demonstrating considerable improvements in terms of extraction speed for MAE. Another way this process is better for the environment is that it usually uses less solvent than the old ways. There is some evidence that MAE may improve the tannin output and compound quality in gallnut extract when administered to the latter. To avoid tannin thermal deterioration, it is crucial to carefully regulate the microwave power and exposure time. There is hope for the industrialization of this method to produce high-quality gallnut extract with optimum tannin concentration through the development of continuous-flow MAE devices.

Conclusion

Solvent choice, temperature, duration, and extraction technique are just a few of the many variables that must be carefully considered in order to optimize the tannin concentration of gallnut extract. You may improve the production and quality of tannins by using modern techniques like ultrasound-assisted and microwave-assisted extraction in addition to enhanced traditional methods. Our extraction procedures and the quality of the final goods will hopefully increase as our knowledge of gallnuts expands. New avenues for the use of gallnut extract should be revealed by this.

At Shaanxi SCIGROUND Biotechnology Co., Ltd., we are at the forefront of plant extract innovation and production. Our state-of-the-art facility, covering nearly 50 acres, boasts an annual output exceeding 5000 tons of high-quality plant extracts, including optimized gallnut extract. Drawing on our broad obvious portfolio and more than a decade of encounter, we give a wide run of items to meet the different needs of the wellbeing nourishment, pharmaceutical, and corrective businesses. Our commitment to quality is apparent in our GMP-compliant fabricating lines and cutting-edge testing offices. Please email info@scigroundbio.com with any questions you may have regarding our gallnut extract or any of our other products.

FAQ

Q: What is the optimal temperature for tannin extraction from gallnut extract?

A: The optimal temperature typically ranges between 50°C and 70°C, balancing extraction efficiency with tannin preservation.

Q: How does solvent choice affect tannin yield in gallnut extract?

A: Solvent choice significantly impacts yield, with organic solvents like ethanol often providing higher yields compared to water alone.

Q: What are the advantages of ultrasound-assisted extraction for gallnut tannins?

A: UAE reduces extraction time and solvent use while potentially increasing tannin yield and preserving heat-sensitive compounds.

Q: How does microwave-assisted extraction compare to conventional methods for gallnut extract?

A: MAE offers faster extraction times and reduced solvent consumption, potentially leading to higher tannin yields in minutes rather than hours.

Q: What are green solvents, and how do they benefit gallnut tannin extraction?

A: Green solvents like deep eutectic solvents are environmentally friendly alternatives that can optimize tannin solubility while reducing ecological impact.

References

1. Zhang, L., et al. (2018). Optimization of ultrasound-assisted extraction of tannins from Chinese gallnut (Rhus chinensis Mill.) and evaluation of their antioxidant activities. Journal of Food Science and Technology, 55(4), 1535-1544.

2. Ferreira, J. P. A., et al. (2019). Microwave-assisted extraction of tannins from Myrica faya: Optimization, characterization and evaluation of biological activity. Industrial Crops and Products, 132, 559-565.

3. Huang, Y., et al. (2020). Comparison of conventional and ultrasound-assisted extraction of tannins from galla chinensis. Chemical Engineering and Processing - Process Intensification, 148, 107811.

4. Li, X., et al. (2017). Deep eutectic solvents as green media for extraction of flavonoid glycosides and aglycones from Platycladi Cacumen. Journal of Pharmaceutical and Biomedical Analysis, 140, 207-213.

5. Chanioti, S., & Tzia, C. (2018). Optimization of ultrasound-assisted extraction of oil from olive pomace using response surface technology: Oil recovery, unsaponifiable matter, total phenol content and antioxidant activity. LWT, 79, 178-189.

6. Xie, D. T., et al. (2015). Microwave-assisted extraction of bioactive compounds from Gallnut of Chinese gall: A review. Food Chemistry, 187, 364-371.