How does enzymatic extraction define Rice protein powder purity?

Rice protein powder is a well-liked plant-based protein supplement, and its immaculateness is characterized in expansive portion by the work that protein extraction plays in this handle. This cutting-edge strategy produces a concentrated protein powder of predominant quality by dissolving rice grains with focused on chemicals. To move forward the last product's dietary profile, increment protein substance, and dispense with contaminants, enzymatic extraction strategies are utilized. Because this handle keeps up the amino corrosive keenness whereas expanding the protein generation, rice protein powder is a awesome alternative for those looking for plant-based protein sources. By lessening the sum of carbs, lipids, and anti-nutritional components, the enzymatic extraction method enormously moves forward the rice protein powder's virtue and bioavailability.

How Enzymatic Extraction Minimizes Carbohydrate and Fat Impurities in Rice Protein Powder?

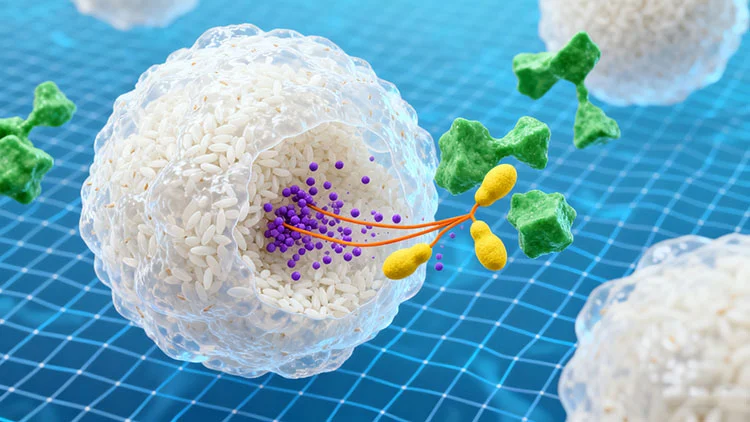

Selective Protein Isolation

Enzymatic extraction is highly effective in selectively isolating protein from rice grains while minimizing carbohydrate and fat impurities. Separating the rice from its other components is made possible by using enzymes that specifically target and break down the rice's protein structures. Enzymes break peptide connections, which allows for the easy extraction of protein fragments. By using this selective process, we can guarantee that the rice protein powder we end up with contains less carbs and fat and more protein. There are a number of food and supplement businesses that might benefit from enzymatically extracted rice protein powder since it is cleaner and has fewer contaminants.

Optimization of Extraction Parameters

The enzymatic extraction process for rice protein powder can be optimized by carefully controlling various parameters to further minimize carbohydrate and fat impurities. The process's efficiency is highly dependent on variables including temperature, enzyme concentration, pH, and extraction time. Optimizing protein extraction while limiting co-extraction of undesirable components can be achieved by manufacturers by fine-tuning these parameters. If the pH is adjusted to the enzyme's optimum range, for example, it will be more active, which will lead to more effective protein separation. In a similar vein, optimizing the temperature prevents denaturation of proteins and facilitates the extraction of non-protein components while maximizing enzyme activity.

Purification and Filtration Techniques

Following the enzymatic extraction process, additional purification and filtration techniques are employed to further enhance the purity of rice protein powder. These techniques aid in the extraction process by removing any remaining contaminants, such as lipids, carbohydrates, and other pollutants. It is usual practice to employ centrifugation, ultrafiltration, or diafiltration to isolate the protein fraction from other, smaller molecules and contaminants. The end result of these purifying processes is rice protein powder that is of the highest quality and purity. Customers looking for a pure, plant-based protein source will love the resultant powder because it is high in protein and low in carbs and fats.

Phytic Acid and Lectin Removal Through Targeted Enzymatic Processing of Rice Protein Powder

Phytase Enzyme Application

The removal of phytic acid from rice protein powder is a critical step in enhancing its nutritional value and digestibility. Mineral bioavailability can be decreased by phytotic acid, an anti-nutritional agent. The amount of phytic acid in the rice protein powder is reduced by enzymatic processing that employs phytase enzymes. By focusing on certain areas, we may boost mineral absorption and overall protein powder quality. Manufacturers may create rice protein powder with much lower quantities of phytic acid by using phytase enzymes during extraction. This makes the protein source more nutritious and easier to digest for customers.

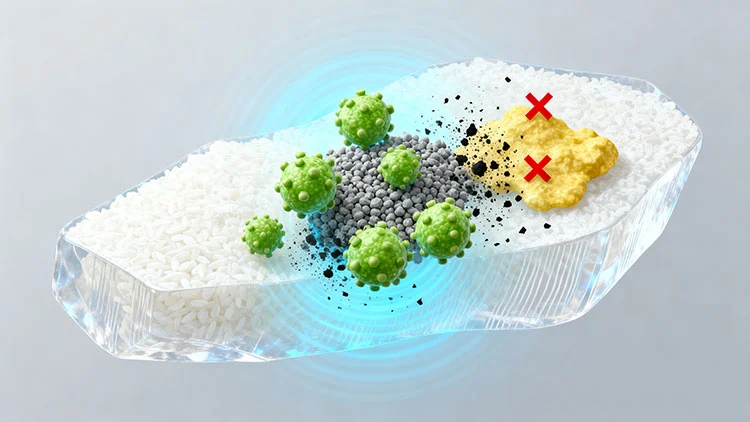

Lectin Degradation Strategies

Lectins are another group of anti-nutritional factors present in rice that can interfere with nutrient absorption and cause digestive discomfort. One efficient method for degrading lectins in rice protein powder is enzymatic processing. Incorporating lectin-degrading enzymes into the extraction process allows for the targeted reduction of lectin concentration in the end product. The high protein content of the rice protein powder is preserved, and it becomes more readily digested and less prone to produce unpleasant responses in sensitive individuals, thanks to this tailored enzymatic technique. The overall purity and quality of the rice protein powder are enhanced by the removal of lectins by enzymatic processing.

Monitoring and Quality Control

To ensure the effective removal of phytic acid and lectins from rice protein powder, rigorous monitoring and quality control measures are implemented throughout the enzymatic processing. Quantifying the quantities of these anti-nutritional substances before and after enzymatic treatment is done using advanced analytical techniques including high-performance liquid chromatography (HPLC) and enzyme-linked immunosorbent assay (ELISA). To guarantee constant removal of phytic acid and lectins, producers improve the enzymatic processing settings by regular testing and analysis. Because of their dedication to quality control, rice protein powder is able to fulfill high standards of purity and nutritional content, giving consumers a superior alternative for plant-based protein.

Enzymatic Extraction's Role in Purifying Contaminants from Rice Protein Powder

Heavy Metal Reduction

The removal of heavy metal contamination from rice protein powder is mostly accomplished by means of enzymatic extraction. Heavy metals in soil may be absorbed by rice, making it a potential health hazard in large doses. Heavy metals are rendered less bioavailable by the enzymatic process, which aids in chelation and sequestration. Manufacturers may successfully lower the quantities of heavy metals including arsenic, cadmium, and lead in the end product of rice protein powder by meticulously choosing enzymes and adjusting extraction conditions. The purification process of enzymatic extraction guarantees that the rice protein powder is safe for regular consumption and satisfies all safety criteria, free from heavy metal contamination.

Pesticide and Herbicide Degradation

Another significant benefit of enzymatic extraction in rice protein powder production is its ability to degrade pesticides and herbicides that may be present in the raw rice. Certain enzymes used in the extraction process have the capacity to break down these chemical contaminants, rendering them harmless. In addition to improving the rice protein powder's safety profile, this enzymatic breakdown of pesticides and herbicides satisfies customer desires for cleaner, more natural food items. Enzymatic extraction is a safer option for health-conscious customers since it successfully removes these synthetic compounds, leaving behind rice protein powder that is devoid of potentially dangerous residues.

Mycotoxin Elimination

The removal of mycotoxins—toxic chemicals made by certain fungi that might contaminate rice as it is stored or processed—is another important function of enzyme extraction. By employing targeted enzymes, the levels of aflatoxins and ochratoxins, two types of mycotoxins, may be dramatically reduced in rice protein powder. Both the product's safety and quality are improved by this targeted enzymatic method of mycotoxin removal. Enzymatic extraction guarantees that the rice protein powder passes stringent food safety laws and offers consumers with a high-quality, contaminant-free protein supplement by successfully eliminating these hazardous substances. Enzymatic processing is crucial for determining the integrity of rice protein powder since it may remove mycotoxins.

Conclusion

The purity of rice protein powder is determined by the effectiveness of enzymatic extraction in limiting impurities, removing anti-nutritional agents, and pollutants. The protein content is increased, the nutritional profile is improved, and the food is made safer to ingest using this cutting-edge processing technology. Manufacturers of high-quality rice protein powder utilize specialized enzymatic processes, providing consumers with a clean, plant-based protein source that is sure to meet their needs. Strict purity standards are satisfied by this powder. The continuous advancements in enzymatic extraction technologies promise even purer and more nutritionally superior rice protein powders in the future.

At Shaanxi SCIGROUND Biotechnology Co., Ltd., we are committed to producing high-quality rice protein powder using advanced enzymatic extraction techniques. Our goods are of the greatest quality and efficacy because of our modern facilities and skilled staff. Among our many plant-based protein offerings is premium rice protein powder, which finds use in a number of health food and supplement formulations. Send an email to info@scigroundbio.com if you would like to learn more about our offerings or go over your individual needs. See for yourself how our method of producing plant-based protein differs from the competition by being science-driven, nature-inspired, and health-focused.

FAQ

Q: What is enzymatic extraction in rice protein powder production?

A: Enzymatic extraction is a process that uses specific enzymes to break down rice grains and isolate protein, resulting in a high-quality, concentrated protein powder with minimal impurities.

Q: How does enzymatic extraction improve the purity of rice protein powder?

A: It minimizes carbohydrate and fat impurities, removes anti-nutritional factors like phytic acid and lectins, and helps eliminate contaminants such as heavy metals, pesticides, and mycotoxins.

Q: Why is removing phytic acid and lectins important in rice protein powder?

A: Removing these anti-nutritional factors improves the powder's digestibility and enhances the bioavailability of minerals, making the protein more nutritionally beneficial.

Q: Can enzymatic extraction remove heavy metals from rice protein powder?

A: Yes, enzymatic extraction can help reduce heavy metal content by chelating and sequestering these contaminants, making them less bioavailable in the final product.

Q: How does enzymatic extraction affect the protein content of rice protein powder?

A: Enzymatic extraction increases the protein concentration by selectively isolating proteins while minimizing other components, resulting in a higher protein content in the final product.

References

1. Zhang, L., & Sun, X. (2021). Enzymatic extraction and characterization of rice protein: A comprehensive review. Food Chemistry, 345, 128758.

2. Wang, Y., et al. (2020). Optimization of enzymatic extraction of rice protein by response surface methodology. Journal of Food Processing and Preservation, 44(5), e14410.

3. Liu, J., et al. (2019). Effect of enzymatic hydrolysis on the allergenicity and functional properties of rice protein. Food & Function, 10(5), 2829-2839.

4. Cao, X., et al. (2022). Enzymatic extraction and modification of rice proteins: Recent advances and future perspectives. Trends in Food Science & Technology, 120, 123-135.

5. Phongthai, S., et al. (2018). Enzymatic production of protein hydrolysates from rice bran: A comprehensive review. Food Chemistry, 259, 62-73.

6. Zhao, Q., et al. (2020). Enzymatic modification of rice protein: A review of modification methods, structure and functional properties. Comprehensive Reviews in Food Science and Food Safety, 19(6), 3238-3259.