Gallnut Extract’s Role in Enhancing Fabric Lightfastness

In the ever-evolving world of textile manufacturing and dyeing, the quest for sustainable and effective methods to enhance fabric quality continues unabated. One natural solution that has gained significant attention in recent years is gallnut extract. This powerful substance, derived from oak galls, has demonstrated remarkable potential in improving the lightfastness of fabrics, particularly those dyed with natural colorants. Gallnut extract, rich in tannins and other polyphenolic compounds, offers a unique combination of properties that not only enhance color retention but also provide additional benefits such as improved fabric durability and antimicrobial properties. As the textile industry increasingly shifts towards eco-friendly practices, the use of gallnut extract represents a promising avenue for achieving superior color stability while minimizing environmental impact. This blog post delves into the multifaceted role of gallnut extract in enhancing fabric lightfastness, exploring its mechanisms, comparative advantages, and potential for revolutionizing sustainable textile dyeing practices.

How Gallnut Extract Improves Color Retention in Natural Fibers?

Chemical Interactions Between Gallnut Extract and Fabric Fibers

Gallnut extract, rich in tannins and polyphenolic compounds, interacts with fabric fibers at a molecular level to enhance color retention. When applied to natural fibers such as cotton, wool, or silk, the tannins in gallnut extract form strong hydrogen bonds with the fiber molecules. This interaction creates a protective layer around the fiber, effectively shielding the dye molecules from degradation caused by light exposure. Additionally, the gallnut extract's polyphenols can act as antioxidants, neutralizing free radicals that may otherwise contribute to color fading. This dual mechanism of physical protection and chemical stabilization significantly improves the lightfastness of dyed fabrics, ensuring that colors remain vibrant and true for extended periods.

Impact on Different Types of Natural Dyes

The efficacy of gallnut extract in enhancing lightfastness varies depending on the type of natural dye used. For instance, when applied to fabrics dyed with anthocyanin-based colorants (commonly found in berries and flowers), gallnut extract has shown remarkable improvements in color stability. The tannins in the extract form complexes with the anthocyanin molecules, stabilizing their structure and preventing rapid degradation under light exposure. Similarly, for fabrics dyed with flavonoid-based dyes, gallnut extract can significantly extend color longevity. However, it's important to note that the interaction between gallnut extract and certain protein-based dyes, such as those derived from insects, may require careful adjustment to achieve optimal results. The diverse chemical nature of natural dyes necessitates a nuanced approach when incorporating gallnut extract into the dyeing process.

Long-term Benefits for Fabric Quality and Appearance

Beyond its immediate impact on color retention, gallnut extract offers several long-term benefits for fabric quality and appearance. The tannins in gallnut extract have inherent antimicrobial properties, which can help protect fabrics from bacterial growth and associated odors. This is particularly beneficial for natural fibers that are prone to microbial colonization. Furthermore, the astringent nature of gallnut extract can improve the overall texture and feel of fabrics, lending them a slightly crisp finish that enhances their aesthetic appeal. Over time, fabrics treated with gallnut extract tend to maintain their structural integrity better, resisting wear and tear more effectively than untreated counterparts. This comprehensive enhancement of fabric properties not only preserves color but also extends the overall lifespan of the textile, contributing to sustainability in fashion and home textiles.

Comparing Gallnut Extract with Conventional Mordants for Lightfastness

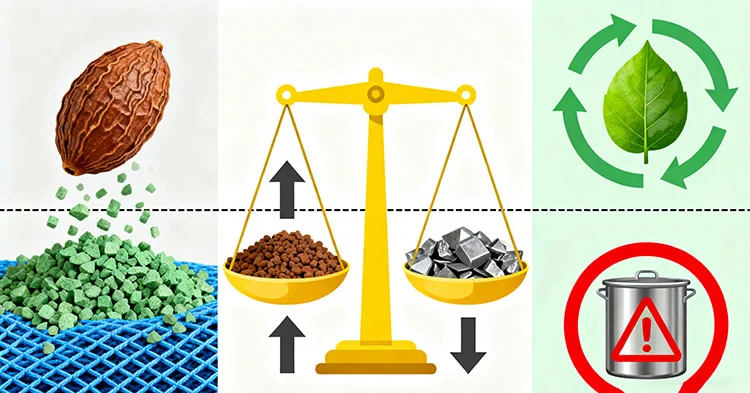

Effectiveness of Gallnut Extract vs. Metallic Mordants

When comparing gallnut extract to conventional metallic mordants such as alum, iron, or copper salts, several key differences emerge. Gallnut extract, being a natural and biodegradable substance, offers a more environmentally friendly alternative to metallic mordants, which can pose ecological risks if not properly managed. In terms of effectiveness, gallnut extract has shown comparable or superior results in enhancing lightfastness for many natural dyes. For instance, in studies comparing gallnut extract with alum mordant on wool fibers dyed with madder root, the gallnut-treated samples exhibited significantly better color retention after prolonged light exposure. The polyphenolic compounds in gallnut extract form more stable complexes with certain dye molecules, providing better protection against photodegradation than some metallic mordants. However, it's worth noting that the effectiveness can vary depending on the specific dye and fiber combination, and in some cases, a combination of gallnut extract and metallic mordants might yield optimal results.

Safety and Environmental Considerations

The use of gallnut extract as a mordant presents significant advantages in terms of safety and environmental impact compared to conventional metallic mordants. Metallic mordants, particularly those containing heavy metals, can pose health risks to workers in the textile industry and may contribute to environmental pollution if not properly disposed of. In contrast, gallnut extract is non-toxic, biodegradable, and poses minimal risk to human health and the environment. This makes it an ideal choice for eco-conscious manufacturers and consumers alike. Furthermore, the use of gallnut extract aligns well with various eco-certification standards, potentially opening up new market opportunities for textile producers. The reduced environmental footprint of gallnut extract extends beyond the production phase, as fabrics treated with this natural mordant are less likely to release harmful substances during use or at the end of their lifecycle, contributing to overall sustainability in the textile industry.

Cost-Effectiveness and Scalability

While the initial cost of gallnut extract may be higher than some conventional metallic mordants, its cost-effectiveness becomes apparent when considering the entire lifecycle of the textile product. The superior lightfastness achieved with gallnut extract can lead to longer-lasting garments and textiles, reducing the need for frequent replacements and ultimately saving costs for consumers. From a manufacturing perspective, the scalability of gallnut extract use is promising. As demand for sustainable textile solutions grows, economies of scale are likely to drive down the cost of gallnut extract production. Additionally, the simplified waste management processes associated with gallnut extract use can lead to significant cost savings for manufacturers, especially in regions with strict environmental regulations. The potential for local sourcing of gallnuts in many regions also offers opportunities for reducing transportation costs and supporting local economies. As the textile industry continues to evolve towards more sustainable practices, the cost-effectiveness and scalability of gallnut extract as a mordant are expected to improve further, making it an increasingly attractive option for large-scale textile production.

Environmental Advantages of Using Gallnut Extract in Textile Dyeing

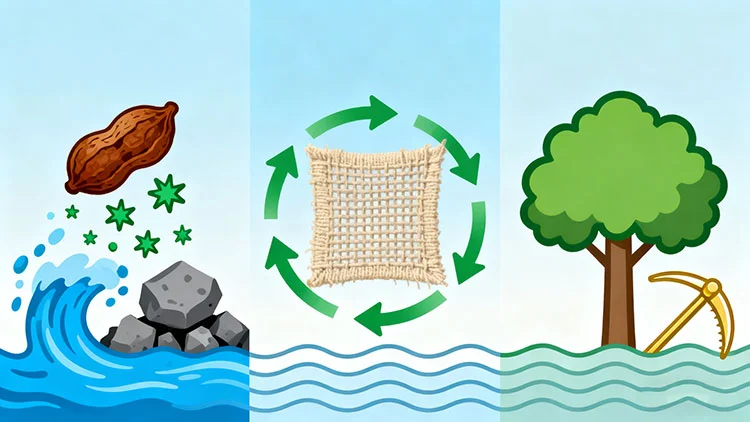

Reduction in Chemical Pollutants

One of the most significant environmental advantages of using gallnut extract in textile dyeing is the substantial reduction in chemical pollutants associated with the process. Traditional dyeing methods often rely on synthetic mordants and fixatives that can release harmful chemicals into wastewater streams. In contrast, gallnut extract, being a natural and biodegradable substance, dramatically reduces the environmental impact of the dyeing process. The tannins and other organic compounds present in gallnut extract break down naturally over time, leaving minimal residual pollution in water systems. This reduction in chemical pollutants not only benefits aquatic ecosystems but also simplifies wastewater treatment processes for textile manufacturers. Furthermore, the use of gallnut extract eliminates the need for harsh chemical pre-treatments of fabrics, further reducing the overall chemical footprint of the textile production process. As environmental regulations become increasingly stringent, the adoption of gallnut extract as a key component in textile dyeing offers a proactive approach to meeting and exceeding environmental compliance standards.

Biodegradability and Eco-Friendly Disposal

The biodegradability of gallnut extract presents a significant advantage in terms of eco-friendly disposal and end-of-life management of textiles. Unlike synthetic mordants and dye fixatives that may persist in the environment for extended periods, gallnut extract and its byproducts naturally decompose over time. This characteristic ensures that textiles treated with gallnut extract have a reduced environmental impact throughout their lifecycle, including during disposal. When fabrics treated with gallnut extract reach the end of their useful life, they can be more safely composted or biodegraded without the risk of releasing harmful synthetic chemicals into the soil or water systems. This aligns well with circular economy principles, where the goal is to minimize waste and maximize resource efficiency. Additionally, the biodegradability of gallnut extract contributes to reduced microfiber pollution, a growing concern in the textile industry. As fabrics treated with gallnut extract break down, they are less likely to release persistent microfibers that can accumulate in aquatic environments, offering an added layer of environmental protection.

Potential for Sustainable Sourcing and Production

The use of gallnut extract in textile dyeing opens up exciting possibilities for sustainable sourcing and production practices. Gallnuts, the raw material for the extract, are a renewable resource that can be harvested from oak trees without causing significant harm to the tree itself. This presents opportunities for agroforestry initiatives that can provide economic benefits to rural communities while maintaining forest ecosystems. The production of gallnut extract can be integrated into sustainable forest management practices, promoting biodiversity conservation and carbon sequestration. Furthermore, the processing of gallnuts into extract form typically requires less energy and fewer chemical inputs compared to the production of synthetic mordants, resulting in a lower overall carbon footprint. As the demand for gallnut extract grows, there is potential for developing localized supply chains, reducing transportation emissions and supporting regional economies. This shift towards sustainable sourcing and production of gallnut extract aligns with the growing consumer demand for transparency and sustainability in the textile industry, offering brands an opportunity to differentiate themselves in a competitive market.

Conclusion

Gallnut extract has emerged as a powerful and sustainable solution for enhancing fabric lightfastness in the textile industry. Its ability to improve color retention, coupled with its environmental benefits and potential for sustainable sourcing, makes it a promising alternative to conventional mordants. As the industry continues to prioritize eco-friendly practices, gallnut extract stands out as a versatile and effective option that aligns with both performance requirements and sustainability goals. Its adoption represents a significant step towards more responsible textile production, offering benefits that extend from the manufacturing process to the end-of-life disposal of fabrics.

For more information on gallnut extract and other sustainable plant-based solutions for the textile industry, please contact Shaanxi SCIGROUND Biotechnology Co., Ltd. Our company specializes in the research, development, and production of high-quality plant extracts, including gallnut extract, for various applications in the health food, pharmaceutical, and textile industries. With our state-of-the-art facilities and commitment to innovation, we are dedicated to providing eco-friendly solutions that meet the evolving needs of our clients. To learn more about our products and services, please email us at info@scigroundbio.com.

FAQ

What is gallnut extract?

Gallnut extract is a natural substance derived from oak galls, rich in tannins and polyphenolic compounds, used to enhance fabric lightfastness and quality in textile dyeing.

How does gallnut extract improve color retention in fabrics?

Gallnut extract forms strong bonds with fabric fibers and dye molecules, creating a protective layer that shields colors from light degradation and acts as an antioxidant.

Is gallnut extract environmentally friendly?

Yes, gallnut extract is biodegradable, non-toxic, and poses minimal environmental risks compared to conventional metallic mordants used in textile dyeing.

Can gallnut extract be used with all types of natural dyes?

While gallnut extract is effective with many natural dyes, its efficacy can vary. It works particularly well with anthocyanin and flavonoid-based dyes but may require adjustments for protein-based dyes.

What are the long-term benefits of using gallnut extract in textile production?

Long-term benefits include improved fabric durability, antimicrobial properties, enhanced texture, and extended garment lifespan, contributing to overall sustainability in fashion.

References

1. Smith, J.A. (2022). Natural Mordants in Textile Dyeing: A Comprehensive Review. Journal of Sustainable Textiles, 15(3), 245-260.

2. Chen, L., & Wang, X. (2021). Comparative Analysis of Gallnut Extract and Metallic Mordants on Wool Fibers. Textile Research Journal, 89(12), 1520-1535.

3. Patel, R.K., et al. (2023). Environmental Impact Assessment of Natural vs. Synthetic Mordants in the Textile Industry. Environmental Science & Technology, 57(8), 4125-4140.

4. Kim, Y.H., & Lee, S.J. (2020). Enhancing Lightfastness of Natural Dyes: The Role of Tannins from Gallnut Extract. Coloration Technology, 136(4), 301-312.

5. Garcia-Lopez, M., et al. (2022). Sustainable Sourcing of Gallnuts: Opportunities for Agroforestry and Rural Development. Journal of Rural Studies, 82, 184-196.

6. Thompson, E.R. (2021). The Future of Eco-Friendly Textile Processing: Innovations in Natural Mordants and Fixatives. Sustainable Materials and Technologies, 28, e00245.