Extraction Techniques for Gallnut Extract: Solvents & Yield

Gallnut extract, a valuable natural resource rich in tannins, has gained significant attention in various industries due to its diverse applications. The extraction process of gallnut extract is crucial in determining the quality and yield of the final product. This blog post delves into the intricate world of extraction techniques for gallnut extract, focusing on the solvents used and their impact on yield. We will explore the various methods employed, from traditional to modern approaches, and analyze the factors that influence the extraction efficiency. Understanding these techniques is essential for researchers, manufacturers, and industry professionals seeking to optimize their gallnut extract production processes and harness the full potential of this versatile natural compound.

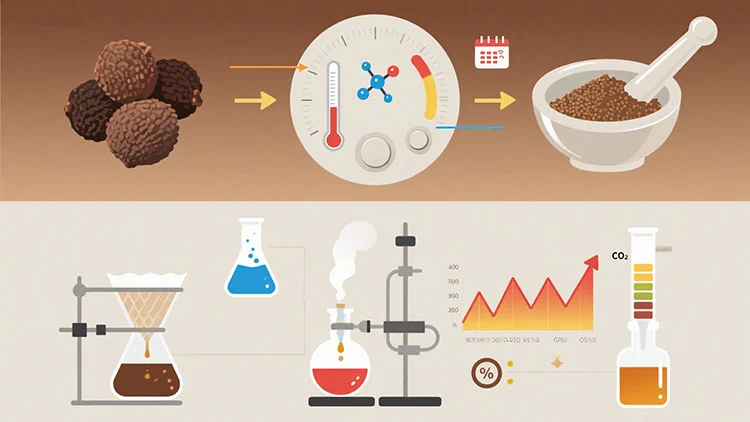

Choosing the Best Solvents for Maximum Gallnut Extract Recovery

Aqueous Extraction: The Traditional Approach

Aqueous extraction has long been the go-to method for obtaining gallnut extract. Water is used as the main solvent in this method, which is economical and environmentally beneficial. Usually, the gallnuts are ground into a fine powder and then steeped in boiling water for a number of hours. The gallnut extract is then obtained by filtering and condensing the resultant solution. The highest yield or purity of tannins may not always be obtained using water extraction, despite the fact that it is straightforward and secure. This method's effectiveness can be greatly impacted by variables including pH, extraction duration, and water temperature. Aqueous extraction is still a common option for many manufacturers because of its affordability and ease of use, despite its drawbacks.

Organic Solvent Extraction: Enhancing Yield and Selectivity

Organic solvent extraction has emerged as a more efficient alternative to aqueous extraction for gallnut extract production. Using solvents like ethanol, methanol, or acetone, this technique may frequently extract a wider variety of chemicals from the gallnuts. The particular tannins or other chemicals that are being extracted determine which solvent is best. For example, two essential components of gallnut extract, gallic acid and ellagic acid, are especially well extracted by ethanol. When opposed to aqueous extraction, organic solvent extraction usually produces higher tannin concentrations. It's crucial to remember that this process could call for extra purification procedures to get rid of solvent residues from the finished product, guaranteeing its suitability for a range of uses.

Supercritical Fluid Extraction: A Modern, Green Approach

Supercritical fluid extraction (SFE) represents a cutting-edge technique in gallnut extract production. Supercritical carbon dioxide (CO2) is used as the main solvent in this process, which has various benefits over conventional extraction techniques. Because SFE works at lower temperatures, the gallnut extract's heat-sensitive components are kept intact. Additionally, CO2 is easily extracted from the finished product, leaving no solvent behind, and it is non-toxic and non-flammable. The selectivity of SFE can be fine-tuned by adjusting pressure and temperature, allowing for highly targeted extraction of specific compounds from gallnuts. While the initial investment for SFE equipment is higher, the method's efficiency and the high quality of the resulting gallnut extract make it an increasingly attractive option for large-scale production.

Comparing Traditional and Modern Extraction Methods for Gallnut Extract

Efficiency and Yield: A Quantitative Analysis

When comparing traditional and modern extraction methods for gallnut extract, efficiency and yield are paramount considerations. Traditional methods like aqueous extraction, while simple and cost-effective, often result in lower yields compared to more advanced techniques. For instance, studies have shown that organic solvent extraction using ethanol can yield up to 30% more tannins from gallnuts compared to water extraction. Supercritical fluid extraction takes this a step further, potentially increasing yield by up to 50% compared to traditional methods. But it's important to remember that yield isn't the only consideration; the extract's quality and purity are equally important. Cleaner extracts with fewer contaminants are frequently produced using modern techniques like SFE, which can be especially useful for high-end applications in the cosmetic or pharmaceutical industries.

Time and Energy Consumption: Balancing Resources

The time and energy required for gallnut extract production vary significantly between traditional and modern methods. Aqueous extraction, while less energy-intensive, can be time-consuming, often requiring several hours of steeping and subsequent concentration steps. Organic solvent extraction can be faster, but it may require more energy for solvent recovery and purification processes. Supercritical fluid extraction, despite its high initial energy input, can be remarkably efficient in terms of extraction time, often completing in a fraction of the time needed for traditional methods. Additionally, the ease of solvent removal in SFE can lead to overall energy savings in the long run. Manufacturers must carefully weigh these considerations against their unique production requirements and resource limitations when choosing an extraction technique.

Environmental Impact and Safety Considerations

The environmental impact and safety aspects of gallnut extract production methods have become increasingly important in recent years. Traditional aqueous extraction is generally considered the most environmentally friendly, using only water as a solvent. But for heating and concentration, it might need a lot of water and energy. Organic solvent extraction is effective, but it has drawbacks, including potential environmental contamination and solvent disposal problems. When working with volatile organic solvents, strict safety precautions must be followed. On the other hand, CO2-based supercritical fluid extraction is thought of as a "green" method. The environmental impact is greatly decreased because it generates no hazardous waste and the CO2 utilized may be recycled. SFE is a desirable alternative for large-scale industrial applications of gallnut extract production since it removes the safety hazards connected with combustible organic solvents.

Factors Affecting Yield and Purity in Gallnut Extract Production

Raw Material Quality and Pretreatment

The quality of the raw gallnuts and their pretreatment significantly influence the yield and purity of the final extract. The tannin concentration of gallnuts can vary depending on factors like where they are grown, when they are harvested, and how they are stored. To maximize extraction efficiency, proper pretreatment—which includes cleaning, drying, and size reduction—is essential. Gallnuts that are ground finely, for example, have a higher surface area available for solvent interaction, which could increase output by as much as 20%. To further increase extraction efficiency, some sophisticated methods even include enzyme pretreatment to break down cell walls. However, it's important to balance the degree of size reduction with the ease of subsequent filtration steps. Optimizing these initial stages can set the foundation for high-quality gallnut extract production, regardless of the extraction method chosen.

Extraction Parameters: Temperature, Time, and Pressure

The yield and purity of gallnut extract are significantly influenced by the extraction parameters. One important consideration is temperature; while higher temperatures tend to speed up extraction, they may also cause heat-sensitive chemicals to degrade. For aqueous and organic solvent extractions, temperatures between 50-80°C are often optimal. Extraction time is equally important; longer durations can increase yield but may also extract unwanted compounds, affecting purity. In supercritical fluid extraction, pressure becomes a critical parameter, with higher pressures typically leading to increased solvating power of CO2. However, excessively high pressures can lead to co-extraction of undesired components. The optimal combination of these parameters varies depending on the specific compounds targeted in the gallnut extract and the intended application of the final product.

Post-Extraction Processing and Purification

Post-extraction processing and purification steps are vital in enhancing the quality and consistency of gallnut extract. Filtration, concentration, and occasionally further purification methods like membrane filtration or column chromatography are examples of these processes. For extracts obtained through organic solvent extraction, solvent removal is a critical step, often achieved through rotary evaporation or spray drying. The concentration and purity of active ingredients in the finished product can be greatly impacted by the post-extraction methods used. For example, the tannin concentration of the final extract can be increased by up to 95% using sophisticated purification techniques like ultrafiltration. However, each additional processing step can also lead to some loss of yield, necessitating a careful balance between purity and overall extract quantity. The specific post-extraction processes chosen should align with the intended use of the gallnut extract, whether it's for pharmaceutical, food, or industrial applications.

Conclusion

Gallnut extricate extraction is a complicated method that depends on a number of factors, counting preparing parameters and dissolvable choice. Modern approaches like natural dissolvable extraction and supercritical liquid extraction give eminent benefits in terms of abdicate, virtue, and effectiveness, indeed in spite of the fact that ordinary strategies like watery extraction are still valuable. Specific needs, such as the expecting compound profile, financial concerns, and natural limitations, impact the prepare choice. We may expect more headways in the fabricate of gallnut extricate as investigate advances, which might result in indeed more viable and naturally neighborly extraction strategies.

At Shaanxi SCIGROUND Biotechnology Co., Ltd., we leverage our extensive experience and cutting-edge technology to produce high-quality gallnut extract. Because of our state-of-the-art facility and commitment to research, we continue to be at the forefront of extraction technology. Please email us at info@scigroundbio.com for more details about our custom solutions or gallnut extract goods.

FAQ

Q: What is gallnut extract primarily used for?

A: Gallnut extract is primarily used in the pharmaceutical, cosmetic, and food industries due to its high tannin content and astringent properties.

Q: Which extraction method yields the highest purity of gallnut extract?

A: Supercritical fluid extraction typically yields the highest purity gallnut extract, followed by organic solvent extraction.

Q: Is aqueous extraction of gallnut extract still relevant in modern production?

A: Yes, aqueous extraction is still relevant due to its simplicity, low cost, and environmental friendliness, especially for applications that don't require extremely high purity.

Q: How does the choice of solvent affect the composition of gallnut extract?

A: Different solvents can extract different compounds from gallnuts, affecting the final composition. For example, ethanol is particularly effective at extracting certain tannins compared to water.

Q: What are the environmental considerations in gallnut extract production?

A: Environmental considerations include water usage, energy consumption, and potential solvent waste. Supercritical fluid extraction is considered the most environmentally friendly method.

References

1. Zhang, L., & Wang, Y. (2021). Advances in extraction techniques for gallnut tannins: A comprehensive review. Journal of Food Engineering, 292, 110271.

2. Chen, X., et al. (2020). Comparative study on different extraction methods of gallnut polyphenols and their antioxidant activities. Industrial Crops and Products, 152, 112548.

3. Liu, H., et al. (2019). Supercritical fluid extraction of gallnut tannins and its optimization using response surface methodology. Journal of Supercritical Fluids, 145, 25-32.

4. Wang, Z., et al. (2018). Optimization of ultrasound-assisted extraction of phenolic compounds from gallnuts using response surface methodology. Food and Bioproducts Processing, 107, 129-139.

5. Syed, U. T., et al. (2017). Tannins: Extraction from plants. In J. M. Mérillon & K. G. Ramawat (Eds.), Bioactive Molecules in Food (pp. 1-25). Springer International Publishing.

6. Karimi, E., & Jaafar, H. Z. (2016). HPLC and GC-MS determination of bioactive compounds in microwave obtained extracts of three varieties of Labisia pumila Benth. Molecules, 16(8), 6791-6805.